The electronics industry has seen strides in the past two decades. Despite that, manufacturers know that they can do more. That’s why they’ll be giving it their all as they enter 2022.

So, what can we expect from the electronics industry in 2022 and beyond? Let’s find out.

#1 New Materials and Architectures

Silicon has been the go-to material for manufacturing electronics for decades. However, it’s a limited resource. Recently, we’ve been feeling the impact of its limited availability as the world suffers because of silicon shortage. Besides, there’s also a limit on how much you can pattern a silicon material.

All these drawbacks are forcing manufacturers to look for alternatives. At present, they’re working with other semiconductor materials to fill that void that silicon will one day leave behind. These materials or composites include gallium nitride and silicon carbide. In 2022, we’ll see manufacturers work with these semiconductors alongside graphene and nanomaterials.

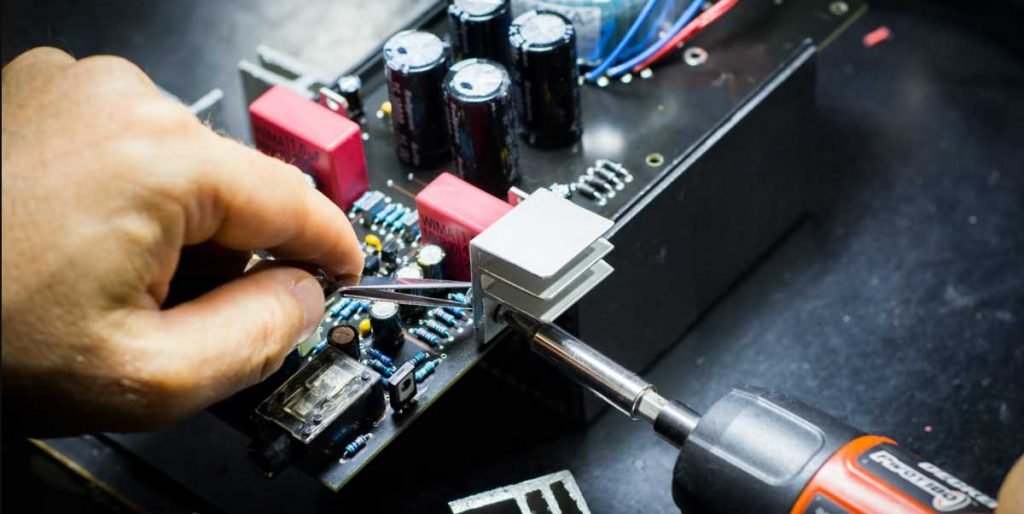

#2 Changes in PCB Repair Technology

Circuit board repair technology has come a long way. Replacing components or repairing physical damage on a printed circuit board is becoming easier. Companies utilize advanced 3D x-ray technology to analyze the damage and make repairs. The use of such technology is helping them retain circuit boards that otherwise would have been rendered useless. Comprehensive Guide to Diagnose PCB Failure.

#3 Organic Electronic Devices

Organic electronics are becoming popular with each passing day. That’s because electronics manufacturers are becoming aware of the necessity of sustainable development. Like many other industries, they too are working to make their production more eco-friendly.

It’s not just about going green. Organic electronics are also cost-effective and offer more flexibility to developers for integrating more components. On top of that, these organic products are lightweight and consume way less power than the inorganic ones.

Microbiological components and biodegradable materials are soon to be favorites of electronics manufacturers. That will reduce the pressure on silicon availability and provide manufacturers with abundant new raw materials.

#4 More Focus on IoT-Based Systems

The Internet of Things is touching our lives in one way or another. We aren’t even aware of their presence in many cases, yet they’re helping us perform many daily tasks.

As we venture into 2022, the IoT revolution will take on an entirely new form. Embedding more precise sensors in electronics for accurate data interpretation will become a trend in 2022. Car manufacturers have been doing this for almost a decade. Now, it’s time we see this trend take off in the electronics industry and find its way into our handheld devices, houses, and workplaces.

#5 Utilizing Artificial Intelligence

AI implementation is becoming a common phenomenon in almost every industry or type of business. The electronics sector is no different.

AI-driven solutions offer manufacturers improved designs and a refined manufacturing process. Currently, the global electronics sector is focusing on rethinking how they carry out their product development cycles. Reducing defects and improving circuit efficiency is their priority right now, and soon, they’ll shift their focus to reduce production downtime.

Manufacturers are keen on exploring how they can implement AI to take circuit designs and automatically make them production-ready. That means developers will no longer have to work with prototypes to manually find defects or faulty components. The AI will do everything for them and do it a lot better.

#6 Better Printing Technologies

Printed electronics have been dependent on membrane switches for more than half a century. However, since manufacturers are innovating in the other departments, they also plan to look into the printing side.

Manufacturers are now working to make RFID, electroluminescent and photovoltaic technologies mainstream when it comes to printing. They firmly believe that the permanent switch to these advanced technologies will enable them to increase production without any added costs.

#7 Optimized IC Packaging

Manufacturers have been utilizing Moore’s Law for scaling electronic devices and packaging ICs. However, it’s an old-school method that hasn’t seen any innovation in some time. So, manufacturers are willing to take on the challenge of finding a better alternative.

Advanced IC packaging will allow manufacturers to stuff complex components and ICs more efficiently. They plan on achieving this using stacked modular components. They are also looking into ways of creating modular circuit designs for better customization of the circuitry.

As manufacturers figure out their ways around these trends, they’ll start to look towards newer ones. Hopefully, we’ll get to see those newer ones soon.